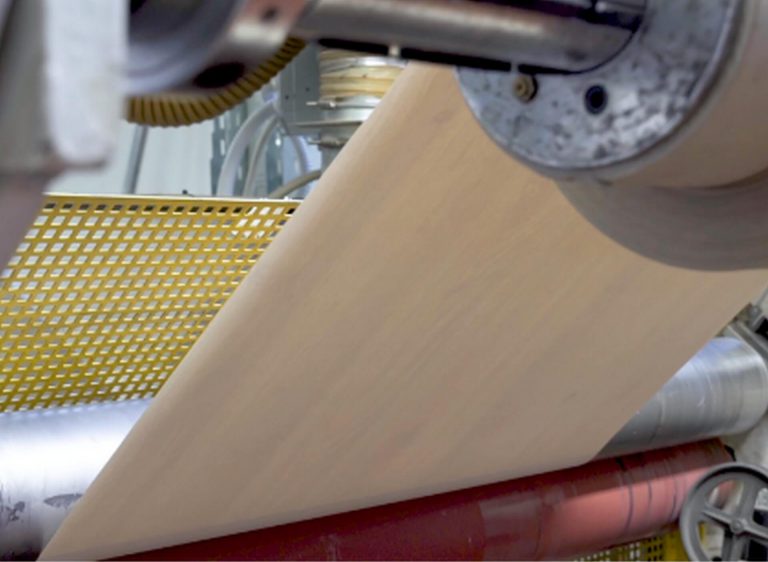

Paper impregnation with resins and additives which make the paper flexible and, in this way, adapt for the coating of every kind of profile and shaped surfaces.

This processing follows the Super Flex impregnation phase. It is possible to change the shade of an already printed paper or produce painted solid colours which are exactly identical to the customer’s reference sample.

Primer application on the back of papers or plastic materials in order to increase the adherence during the profiles and panels coating phase.

Different finishes are available: High Gloss UV and Matt finishes, light and heavy embossed finishes and “Pelle di pesca” finish. It is also possible to impress five different kinds of pores: Oak, Larix, Stone, Wood and Space.

It is possible to apply a film on papers, plastic materials and finished panels in order to protect the materials during the processings. The film can be transparent or coloured and of different thicknesses depending on the resistance needed.

Coupling papers allows us to create different thicknesses of articles by coupling the decorative paper to PVC, Alkorcell, paper or Woven-non-woven scrim supports.

Always up to date with technology, we added to our plant systems two digital printing machines designated to the customization of coating papers, but also products for the interior design. Check out our Digital Area for further information.

We also offer the services of paper cutting in slices requested by the customer and reels rewinding.

We also offer a panels calendering service. It is possible to calender panels of different thicknesses and with different materials such as papers or plastic materials.